- Top layer: Procell EVA designed to provide cushioning and reduce abrasions

- Middle layer: Poron foam designed to absorb shock

- Bottom layer: EVA foam, Durometer measurement of 40, holds the contoured shape of the insert

Inserts

-

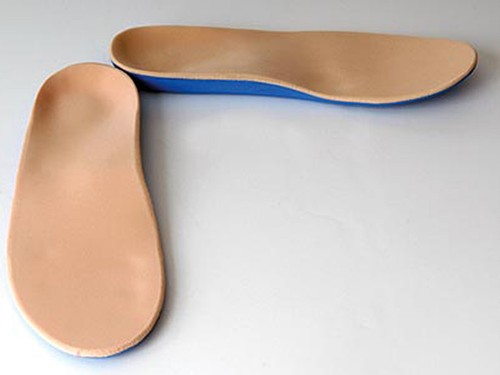

Toe Fillers (L5000) Made specifically for patients with Digital, Hallux, and Trans-Metatarsal amputations, these prosthetic devices are eligible for Medicare reimbursement and billable using the L5000 code through the Healthcare Common Procedure Coding System. Toe Filler inserts are simply Custom Inserts, made of high-quality EVA foam crafted with 3D scanning technology and cut with computer-aided routers, combined more material to fill the void left by an amputation procedure. Such orthotic devices eliminate the need for a separate insert for the affected foot. Features: A lot goes into making finely crafted custom inserts such as those pictured, left, which consist of three layers of material for maximum comfort:

Toe Fillers (L5000) Made specifically for patients with Digital, Hallux, and Trans-Metatarsal amputations, these prosthetic devices are eligible for Medicare reimbursement and billable using the L5000 code through the Healthcare Common Procedure Coding System. Toe Filler inserts are simply Custom Inserts, made of high-quality EVA foam crafted with 3D scanning technology and cut with computer-aided routers, combined more material to fill the void left by an amputation procedure. Such orthotic devices eliminate the need for a separate insert for the affected foot. Features: A lot goes into making finely crafted custom inserts such as those pictured, left, which consist of three layers of material for maximum comfort: -

Custom Inserts State-of-the-art scanning technology, courtesy of Medical Resources Limited (MRL), provides an accurate 3D impression utilized for a custom fit, tri-laminate foam insert that is Medicare-approved and specially tailored to accommodate the diabetic foot. Computer Numerical Control (CNC) routers enable Stride Lite technicians to bring these images to life precisely and efficiently, creating perfect replicas ready to wear in virtually no time. Features: A lot goes into making finely crafted custom inserts such as those pictured, left, which consist of three layers of material for maximum comfort:

Custom Inserts State-of-the-art scanning technology, courtesy of Medical Resources Limited (MRL), provides an accurate 3D impression utilized for a custom fit, tri-laminate foam insert that is Medicare-approved and specially tailored to accommodate the diabetic foot. Computer Numerical Control (CNC) routers enable Stride Lite technicians to bring these images to life precisely and efficiently, creating perfect replicas ready to wear in virtually no time. Features: A lot goes into making finely crafted custom inserts such as those pictured, left, which consist of three layers of material for maximum comfort:- Top layer: Procell EVA designed to provide cushioning and reduce abrasions

- Middle layer: Poron foam designed to absorb shock

- Bottom layer: EVA foam, Durometer measurement of 40, holds the contoured shape of the insert

-

Stride Lite Heat Meticulously crafted with three layers of shock-absorbing foam, this Medicare-approved, full-length, tri-laminate insert can be heat-molded to suit the unique contours of any Diabetic foot. Individually tailored to provide total contact with the entire foot, including the base and the arch. Features/Process: A lot goes into making finely crafted custom inserts such as those pictured, left, which consist of three layers of material, heat-moldable to the foot for maximum comfort:

Stride Lite Heat Meticulously crafted with three layers of shock-absorbing foam, this Medicare-approved, full-length, tri-laminate insert can be heat-molded to suit the unique contours of any Diabetic foot. Individually tailored to provide total contact with the entire foot, including the base and the arch. Features/Process: A lot goes into making finely crafted custom inserts such as those pictured, left, which consist of three layers of material, heat-moldable to the foot for maximum comfort:- Top layer: Procell EVA designed to provide cushioning and reduce abrasions

- Middle layer: Poron foam designed to absorb shock

- Bottom layer: EVA foam, Durometer measurement of 40, holds the contoured shape of the insert

- Use external heat source, 230 degrees Fahrenheit or higher, to mold insert to foot, providing total contact with the heel and arch * According to guidelines, additional arch modifiers may be necessary to maintain total contact depending on arch height.